DMT® FAQ

DMT® FAQ

- Are all diamond sharpeners the same?

- Are all DMT products made in the USA?

- I’m interested in buying your products. Could you please send me a price list?

- Where can I buy your sharpeners?

- Which grit should I use?

- What is the warranty on your sharpeners?

- How long should the diamond last on a sharpener?

- What are the differences in the DMT diamond surfaces?

- How do I take care of my diamond sharpener?

- Do you have anything that I could use to sharpen my bread knife or serrations on a folding knife?

- I have ceramic knives. Can I use any of your diamond stones to sharpen them?

- What are the seven settings on the Aligner™ Guide?

- I think my sharpener may have worn out, what do I do?

- I know it says to use the sharpener dry or with water, but can I use oil anyway? Can I store my DMT stone in kerosene?

- I have a DMT® sharpener and I can’t seem to get my knife sharp. What am I doing wrong?

- My DuoSharp® bench stone has holes on one side; what are these?

- Which product is the best to use to flatten my Japanese water stones?

-

Are all diamond sharpeners the same?

No, there is no substitute for the quality of DMT® brand sharpeners. The difference is in the performance and durablility of the products – we call the DMT Difference™. This is why DMT products have a worldwide reputation for excellence. The difference starts with quality and consistency of the diamonds, in our manufacturing process and the tighter tolerances to maintain flatness.

-

Are all DMT products made in the USA?

Not only are all our products made in the US, but we work very hard to source our packaging, printing and displays from local manufacturers where possible.

-

I’m interested in buying your products. Could you please send me a price list?

We are happy to send you an illustrated price catalog. To download from our website, go to Product Catalog and Brochures. From here you can click on our catalog and/or price list.

To request a catalog/ price list be mailed to you, use this link Contact Us and in the drop down menu, select Catalog Request or call us toll free at 800-835-2263.

-

Where can I buy your sharpeners?

DMT products are available nationwide through many hardware chains, professional tool distributors, camp/sport stores, wood & craft stores, and cutlery stores as well as many online merchants.

Click on the link below for a list of retailers, including telephone numbers and web site links where DMT products can be sourced.

Dealer List Or go to our newest outlet: The DMT® Online Store

If you need further assistance, contact our Customer Service Department toll free at 800-835-2263, ext. 1 or contact us using our Customer Service Email Form.

-

Which grit should I use?

Which grit you should use depends on: How often you sharpen; how dull your knife or tool edge is; how sharp you want your edge; the work the edge will do – rougher work, coarser grit – finer work, finer grit. Think about this as you review the diamond grit choices.

Hint: The pros use more than one grit moving from coarser to finer grits as they sharpen. Your best value for 2-grit sharpening is with our Double-sided Diafold® hand-held sharpeners or DuoSharp® bench stone models.

If you’re still not sure, call Customer Service at 800-835-2263, ext. 1. Our office is open Monday – Friday, 8:00 a.m. to 5:00 p.m. ET.

STANDARD DIAMOND GRITS:

Extra-Extra Coarse – Recommended for extreme stock removal to repair a much damaged edge or to quickly change a bevel angle. This grit is a safe alternative to power grinding, cutting quickly without heat build-up that can ruin tool temper. Unless the stone is designated “Diaflat” (that is, designed for flattening other stones), DMT does not recommend using for flattening waterstones, Arkansas stones, and synthetic stones.

Color code: silver. Diamond size: 120 micron (120 mesh).

Extra-Coarse – Recommended for aggressive removal of metal on damaged tools or for heavy-duty outdoor tools such as axes and lawn mower blades. This grit is commonly used as the first step in flattening the backs of chisels and plane irons and for rapid stock removal from a chipped or damaged edge. Unless the stone is designated “Diaflat” (that is, designed for flattening other stones), DMT does not recommend using for flattening Japanese waterstones.

Color code: black. Diamond size: 60 micron (220 mesh).

Coarse – Quickly restores a dull edge to cutting sharp. Customers that desire cutting fast action without worry of edge refinement often use our coarse models. Unless the stone is designated “Diaflat” (that is, designed for flattening other stones), DMT does not recommend using for flattening Japanese waterstones.

Color code: blue. Diamond size: 45 micron (325 mesh).

Fine – Restores to a fine edge any knife or tool that is slightly dull. Many of our customers consider the fine grit to be a medium/all purpose sharpener. Professional Chefs and gourmet cooks work through to our finer grit models. For woodworkers and sportsman who are stepping through the grits, it’s the edge refinement step done before micro beveling and polishing.

Color code: red. Diamond size: 25 micron (600 mesh).

Extra-Fine – Refines knife or tool edge to razor sharp perfection.

Color code: green. Diamond size: 9 micron (1200 mesh).

Extra-Extra Fine – Provides the finest grade micronized bonded diamond abrasive available anywhere for the ultimate edge refinement, achieving quick stock removal with millions of diamond cutting edges. Prior to break-in, using the extra-extra fine diamond will result in a matte to shiney finish (scratch pattern evident) on your edge or bevel; once fully broken in, you will achieve a lusterous finished edge.

Color code: tan. Diamond size: 3 micron (8000 mesh).

HARDCOAT DIAMOND GRITS:

HC™ Extra-Extra Coarse Diaflat® – Designed specifically for flattening waterstones, Arkansas stones, and synthetic stones. Use the 120 micron for flattening 1000 grit/mesh and coarser stones; use the 95 micron for finer grit stone flattening.

Color code: silver. Diamond size: 120 micron (120 mesh), 95 micron (160 mesh)

HC™ Fine – Designed to withstand the rigors of sharpening ceramic knives; perfect to use with hard steels as well. Restores to a fine edge any knife or tool that is slightly dull. Many of our customers consider the fine grit to be a medium/all purpose sharpener. Professional Chefs and gourmet cooks prefer using our fine grit models. For woodworkers and sportsman who are stepping through the grits, it’s the edge refinement step done before micro beveling and polishing.

Color code: white/HC marked. Diamond size: 25 micron (600 mesh).

HC™ Extra-Fine – Designed to withstand the rigors of sharpening ceramic knives; perfect to use with hard steels as well. Refines knife or tool edge to razor sharp perfection.

Color code: white/HC marked. Diamond size: 9 micron (1200 mesh).

-

What is the warranty on your sharpeners?

The DMT® Commitment: Since 1976, DMT has been committed to innovate and produce the world’s finest diamond knife and tool sharpeners. All DMT products are made using the highest quality materials and workmanship and are guaranteed to be free of defects. Should you have an issue, please call our customer service specialist to assist you. If your product fails to perform due to defects in materials or workmanship, we will replace it regardless of age. Normal wear, industrial use or abuse, misuse or neglect is not covered. Defective products will be replaced with the same product or one of equal value. Send the product in its original box for proof of purchase along with an explanation of defect.

-

How long should the diamond last on a sharpener?

It depends on how often you use it, if you use it properly, and if you keep it clean and properly stored. When used properly, kept clean and stored dry, DMT diamond sharpeners will last a very long time. They do not last forever, but they last for several years. If you use your sharpener as part of your daily work and use it many times a day, you will likely need to replace it in a few years after extraordinary service. If you use your sharpener to sharpen your kitchen knives every so often, chances are your sharpener will last ten or more years. Some of our customers report their DMT® sharpeners are still performing after twenty years of service!

-

What are the differences in the DMT diamond surfaces?

It is important to note that all DMT diamond products are manufactured to the same high standard using the same high-quality micronized monocrystalline diamond that makes sharpening with DMT products consistently reliable and superior. Therefore, the difference between the two diamond product lines becomes a matter of preference to the user.

The Diamond Whetstone™ and DuoSharp® lines: These products carry our signature polka dot pattern surfaces. The polka dots are slightly recessed so that when you are sharpening the small amount of material (swarf) that is being removed will fall into the polka dots and remain out of the way of the sharpening surface, making your sharpening work quick and easy.

The DiaSharp® line: These products have a continuous diamond surface, which makes them perfect for small-pointed tools as well as your other sharpening needs. They are constructed of solid steel, which makes them heavier than our engineered-resin Diamond Whetstone™ and DuoSharp® lines.

When compared with conventional sharpening stones, all DMT products work faster and sharpen quickly using light pressure and rest assured that your DMT stone remains flat!

-

How do I take care of my diamond sharpener?

Important: Always clean the tool to be sharpened before you sharpen it.

When you first use your DMT® sharpener, the diamond surface will seem aggressive in nature; the diamond sharpener will smooth after initial sharpening with no impact to long term performance. Your first few sharpenings are the break-in period.

To maintain your sharpener, you should clean after each use with water and wipe dry. After several sharpenings, use a mild kitchen abrasive cleanser and a nylon scrub brush (an old toothbrush works well too). Make sure the sharpener is dry before putting it away.

Storing your DMT stone: Always put away dry and store in a dry area. Use leafing (paper towels, cloth, plastic storage bag) in between your bench stones to prevent abrasive sides from rubbing.

For use and care: Product Catalog and Brochures

-

Do you have anything that I could use to sharpen my bread knife or serrations on a folding knife?

Yes! DMT’s Diafold® Serrated Knife Sharpener with its tapered cone shape is perfect for sharpening the wide serrations on a bread knife, the smaller serrations on a pocket or folding knife and anything in between. Since the rod is tapered, a variety of sizes of serrations can easily be sharpened using DMT’s Diafold® Serrated Knife Sharpener. For extra large bread knife serrations, you can use DMT’s Diamond Steel™ Sharpener.

-

I have ceramic knives. Can I use any of your diamond stones to sharpen them?

The only abrasive strong enough to sharpen ceramic is diamond. Any of our diamond stones can sharpen ceramic knives, but since ceramic is an aggressive abrasive as well, it will reduce the life of your diamond stone. DMT’s Hardcoat™ sharpening surface is designed to withstand the rigors of ceramic sharpening as well as sharpen any knives and other edges you may have.

Find available HC™ products here: https://www.dmtsharp.com/sharpeners/specialty/hardcoat-surface-sharpeners/

-

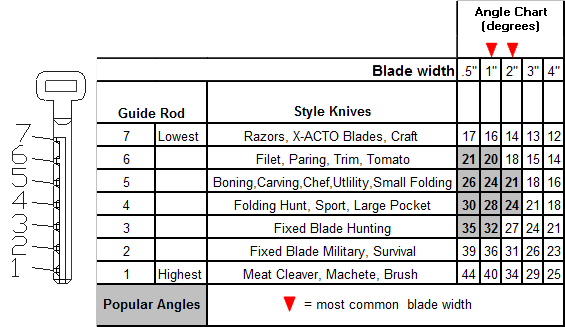

What are the seven settings on the Aligner™ Guide?

The exact angle on the Aligner™ Guide will depend on the knife you are using with it. See the diagram below. Based on a 1” blade, the settings range from 16 degrees (shallowest) to 40 degrees (steepest). The seven choices are: 16, 20, 24, 28, 32, 36, and 40 degrees. As you extend the guide rods out on the knife clamp, the angle of your knife becomes steeper relative to the diamond sharpener.

-

I think my sharpener may have worn out, what do I do?

First, clean it. If you have not cleaned your sharpener on a regular basis, the surface could be loaded up with metal fines (also known as “swarf” buildup) which clog the stone surface affecting its performance. If you are concerned that the diamond may have worn off the stone, rub the sharpener against an old glass jar. If the sharpener scratches or frosts the glass, then there is diamond on the sharpener ready for your sharpening needs.

-

I know it says to use the sharpener dry or with water, but can I use oil anyway? Can I store my DMT stone in kerosene?

DMT recommends you use DMT products dry or with water only. Although mineral oil or WD40 will not harm the DMT products, they can impede sharpening if used in excess and can damage the sharpener overtime if not properly cleaned/removed from the sharpener. DMT recommends that you always wipe your Diamond Sharpeners clean and store dry after use. Put away your benchstones dry and store in a dry area. Use leafing (paper towels, cloth, plastic storage bag) in between your bench stones to prevent abrasive sides from rubbing.

-

I have a DMT® sharpener and I can’t seem to get my knife sharp. What am I doing wrong?

Chances are you are not maintaining a constant angle. We recommend sharpening at a 20-degree angle. That means positioning the knife so it is resting on the sharpener at about 20 degrees. If you are unsure about the angle, approximate by lying two quarters on the bench stone and rest the knife on it. Another method is to hold your knife at 90-degrees to the sharpening surface, then half that to 45-degrees and half again to 22.5-degrees. However, sharpening at the proper angle is not as important as sharpening at a constant angle.

To achieve this consistent angle, lock your wrist. If your wrist wobbles it won’t keep the knife at a constant angle. If you are new to sharpening and you’re not sure if you are holding the knife at a proper angle, we recommend the following:

Use a black marker and draw a line on the bevel of the knife. The bevel is the shiny part at the edge of the blade that has a different angle to it (that’s that part that does the cutting). After you have drawn a line on the knife bevel, sharpen the knife. Look at the bevel (edge) to see if all the black is gone. If it isn’t, you can see whether you need to raise or lower the knife angle during sharpening—by raising or lowering your locked wrist.

If you need further assistance, call Customer Service toll free at 800-835-2263, ext. 1. Our office is open Monday – Friday, 8:00 a.m. to 5:00 p.m. ET.

For use and care: Instrucions

-

My DuoSharp® bench stone has holes on one side; what are these?

The holes are there as a by-product of the manufacturing process and in no way affects the peformance of the bench stone.

-

Which product is the best to use to flatten my Japanese water stones?

DMT has engineered a product designed specifically for this purpose; the DMT Dia-Flat® Lapping Plate. Available in 2 grit sizes: 95 micron (160 mesh) for finer grit stones or 120 micron (120 mesh) for 1000 grit and coarser stones.

Both are designed to quickly flatten waterstones or any other type of sharpening stone. The Dia-Flat® is able withstand the extreme service conditions incurred when flattening other abrasive sharpening stones due to the proprietary DMT® Diamond Hardcoat™ process.

Use under running water or submersed in a pan of water for best results in order to quickly flush away the slurry that is generated when flattening. Abrade the surface to be flattened across the Dia-Flat® surface using long overlapping strokes in a figure “8” motion and light to moderate force – be sure to use the entire Dia-Flat® surface. A figure “8” motion promotes even, consistent wear of the stone being flattened and the Dia-Flat® Lapping Plate. The figure “8” motion and finishing with lighter pressure will reduce any scratches from the flattening process. (For complete instructions refer to below link.)

IMPORTANT: Do not use in a sink that has a garbage disposal unit as the slurry is detrimental to the disposal bearings.

Always clean/dry your DMT Dia-Flat® after each use as build up of material on the stone from flattening may be significant.

Use and care: Instructions

Diaflat Instructions. DiaFlat Video

Some DMT Diamond Sharpeners could be used (and have been used) for flattening, however, they were designed for sharpening, not flattening, therefore, DMT assumes no liability for sharpening stones worn out due to this method of use.